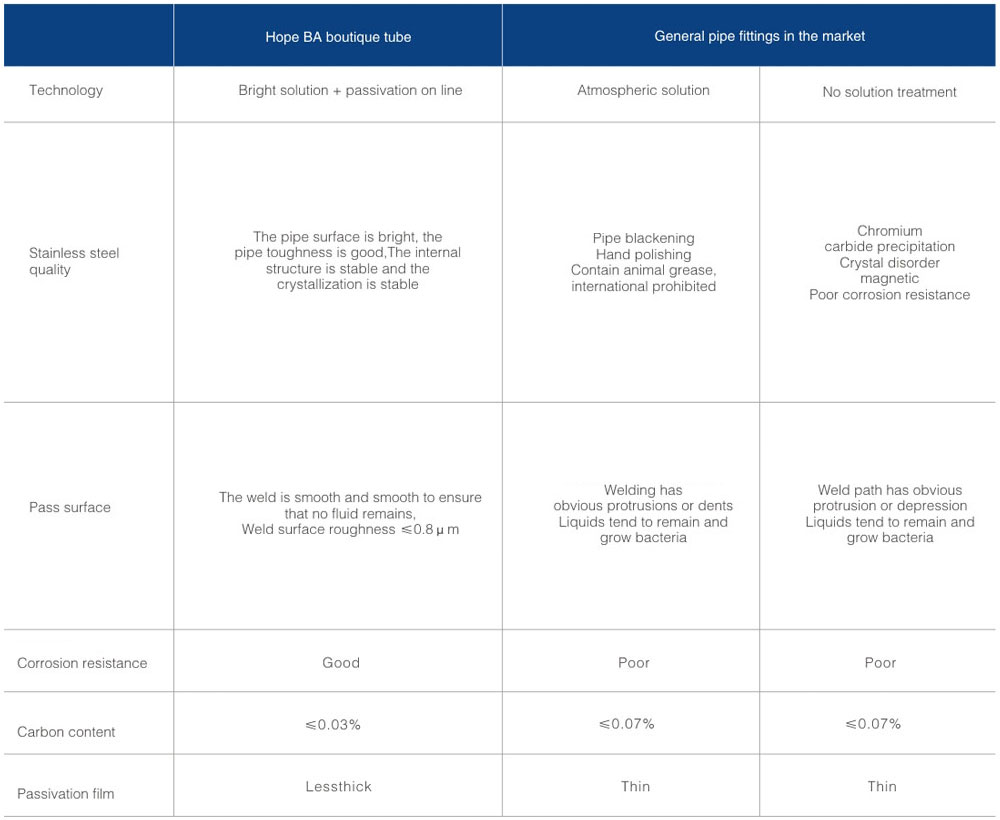

Hope BPE pipe fittings using online solution technology, stainless steel surface bright, strong toughness, no intergranular corrosion phenomenon, smooth weld, not easy to crack, good corrosion resistance.

Hope produce ASME-BPE and ASTM A270 S2 specifications tubes,We only use Outokumpu Material for ASME BPE products.

All of these tubes are polihsed both in ID AND OD.

It is possible to control the sulfur content in the steel pipe to 0.005-0.007, which is more conducive to orbital welding.

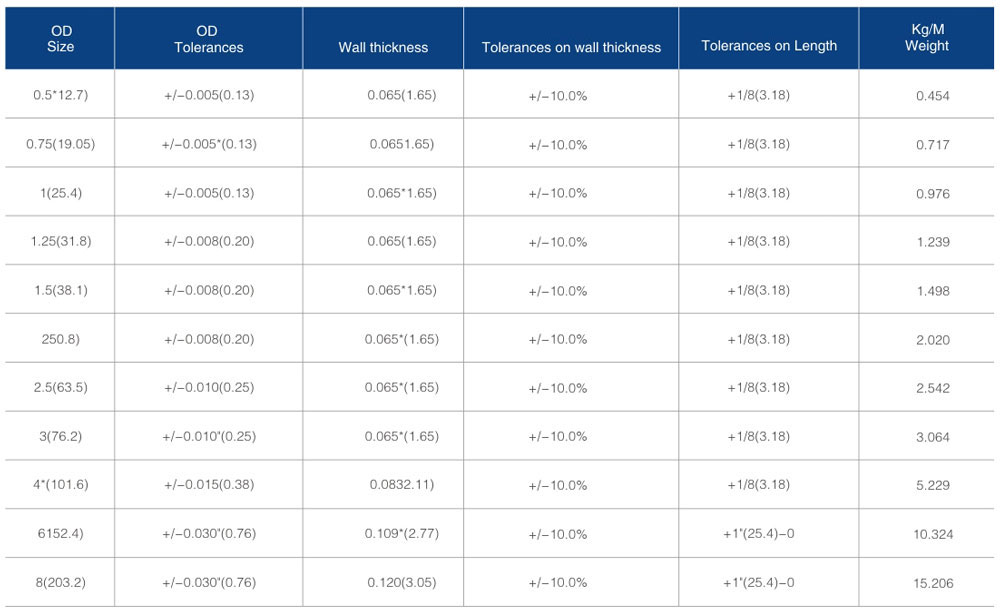

Hope can provide 1/2 inch to 8 inch ASME BPE tubes in 6 meter or 6.1 meter.